This work was done as a part of my Ph.D. at the Indian Institute of Science, Bangalore.

Recent advances in the manufacturing processes using laser have led to increased use of advanced and dissimilar materials. Laser welding is a versatile technique with chemically pure heat source and a good control over power level to join extremely thin as well as very thick plates.

There is a lot of literature available on joining of similar metals/alloys. Not much, however, is known about dissimilar metal joining, which promises an important role in future.

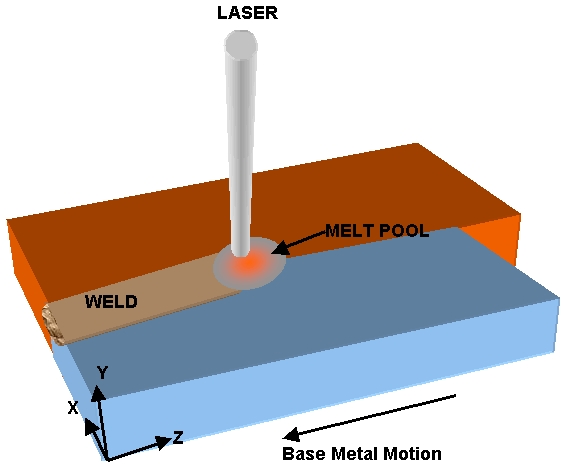

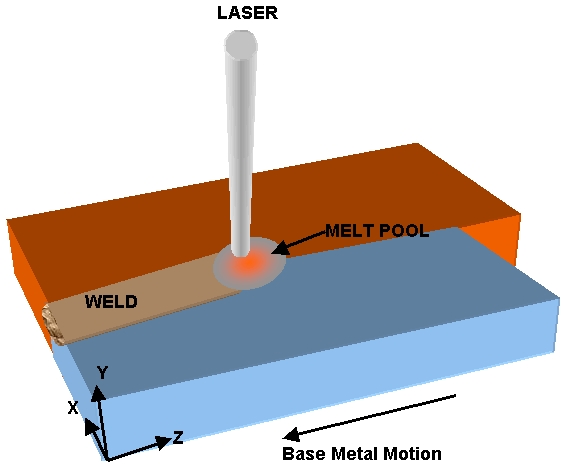

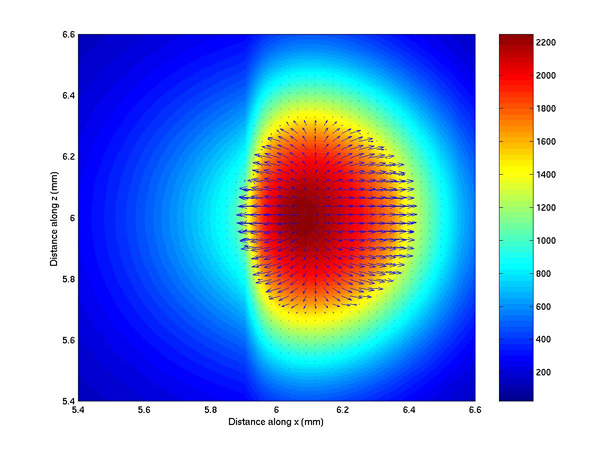

Figure on the right shows a schematic of Laser Welding Setup : Butt weld with gaussian heat source applied symmetric about the centerline on the top

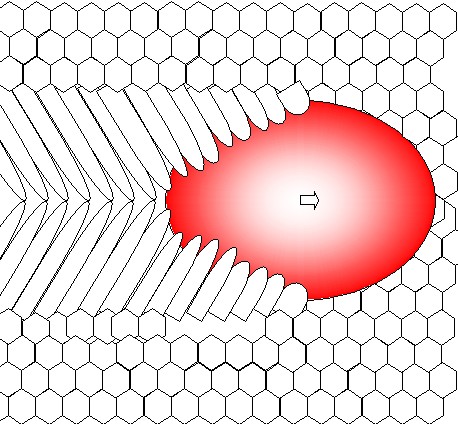

Butt Welding of similar metals/alloys with the heat source placed symmetrical about the centerline on the top would usually lead to microstructural features that are well documented. Weld pool solidification takes place by continuous growth of base metal grains leading to columnar grains with a weld-centerline or equiaxed grains at the centre of the weld. The shape of the weld pool is symmetric about the centerline.

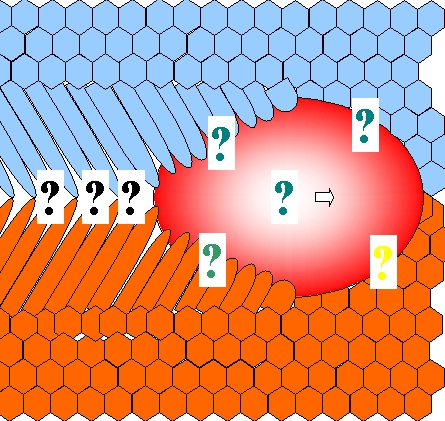

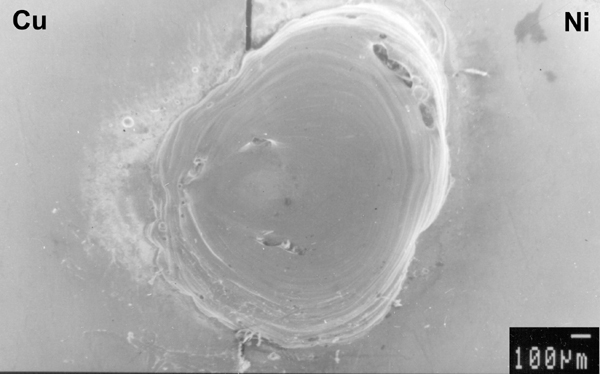

However, during welding of dissimilar metals, there are many interesting features that are not completely understood. Physical properties of the two metals being very different from each other lead to complexities in weld pool shape, solidification microstructure and segregation patterns.

|

|

| Welding of similar metals/alloys | Welding of dissimilar metals/alloys |

The focus was on characterization and modeling aspects. Optical microscopy, Scanning Electron Microscopy, EDS and Transmission Electron Microscopy are used to characterize the microstructure. The welding experiments are done in collaboration with laser processing group of Technical University of Clausthal.

Systems studied were Copper-Nickel and Iron-Copper. Pure metals were chosen for simplicity and ease in fundamental understanding. Iron-copper system has solid state immiscibility and liquid miscibility. Copper and nickel have different physical properties but have complete miscibility in solid and liquid states and provide an ideal system for a detailed analysis.

A computational modelling of the transport phenomena that take place during laser welding of dissimilar metals of was developed using control volume formulation. Since the process is inherently three dimensional in nature, a 3D transient model was developed to calculate conservation of mass, momentum, enthalpy and composition. The model uses Patankar’s SIMPLER algorithm. The program is written in Fortran 90. Visualization is done using Matlab and Tecplot. The computational facilities are provided by Supercomputer Education and Research Centre, Indian Institute of Science.

Please Note that the soft copies of the papers are subject to copyright restrictions of the respective publishers.