This work was part of a project sponsored by NRB Materials Panel with Prof. K. Prasad Rao as principal investigator. This work was executed mainly by Dr. H. Khalid Rafi, jointly guided towards his Ph.D. by Prof. K. Prasad Rao and myself. The work was also in collaboration with Prof. K. Prasad Rao (retired from IIT Madras), Prof. G. D. Janaki Ram (now with IIT Hyderabad) and Prof. Krishnan Balasubramanian. All the processing work was performed on an indigenous machine in our lab.

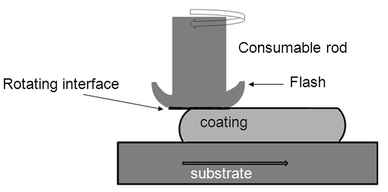

Figure shows a schematic of the process is reproduced from Ref [4]. Friction surfacing is studied extensively to obtain coatings of different steels on MS base. Direct thermal measurements using high speed infrared camera measurements [3] show that initially the heating is by friction and once the consumable rod sticks to the base, temperature rises suddenly due to dissipative heating through plastic deformation.

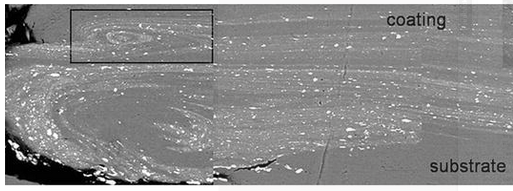

Figure shows a backscatter electon image of the cross-section of the coating is reproduced from Ref [4]. Tungsten particles are used as tracer particles. Back scattered electron microscopy reveals the location of these particles in the surface coating. Originally they were all at the center of the consumable rod.

Please Note that the soft copies of the papers are subject to copyright restrictions of the respective publishers.